We promote a healthy planet by buying our timber only from FSC certified mills in the US. The Forest Stewardship Council (FSC) ensures that the forest of origin meets strict environmental, social, and economic standards, supporting sustainable practices that protect biodiversity, conserve natural habitats, and respect the rights of local communities and indigenous peoples.

Our customers can trust that their purchase supports responsible forestry, contributing to the preservation of forests and the promotion of sustainable practices worldwide.

We exclusively use premium FAS grade timber, ensuring high quality on both sides, making our boards truly reversible. As shown in the graph, FAS grade timber costs three times more than lower grades. For our solid boards, we use FAS Wide grade timber, which costs five times more than lower grades due to its rarity and is the most expensive timber available.

Our boards feature a juice groove on one side and plain on the other to use as you prefer. We include a friction mat for stability, and optional feet for if you prefer. Combining exceptional craftsmanship and functionality, our boards are designed to meet all your cutting needs with ease and style.

We believe delamination, or the opening up of joints, is the biggest enemy of cutting boards, leading to bacterial growth and a shortened lifespan. Delamination can be hairline cracks or large, trapping food particles and allowing bacteria to thrive.

We are unique in the world to offer two solutions to eliminate delamination.

First, we offer solid, one-piece boards (image 1) which can never delaminate. These are cut from the centre of large diameter logs (image 3). These are rare and very expensive to source.

Second, we offer end grain boards made with 2-inch wide timber (image 2) in a staggered design bonded with Titebond III food-safe glue and reinforced with stainless steel screws (image 4). These end grain boards behave like one-piece and will never delaminate.

We want to be known for our dedication to safer cooking, and follow a three-step integrated approach to meet this objective:

1) One-piece approach to prevent delamination: our boards are made from one solid piece of timber (photo 1), or end steel reinforced (photo 2, X-ray shown) end-grain boards which are made “as if one piece”

2) Reduce moisture continent to below 5% (photo 3) using our proprietary vacuum drying process to stabilise the timber and allow deeper penetration with oil

3) Immerse the boards overnight in Wahlch Silverpro antibacterial cutting oil. The oil penetrates deep into the grains (photo 4), and during everyday use kills 99% bacteria on contact, protecting even knife gashes.

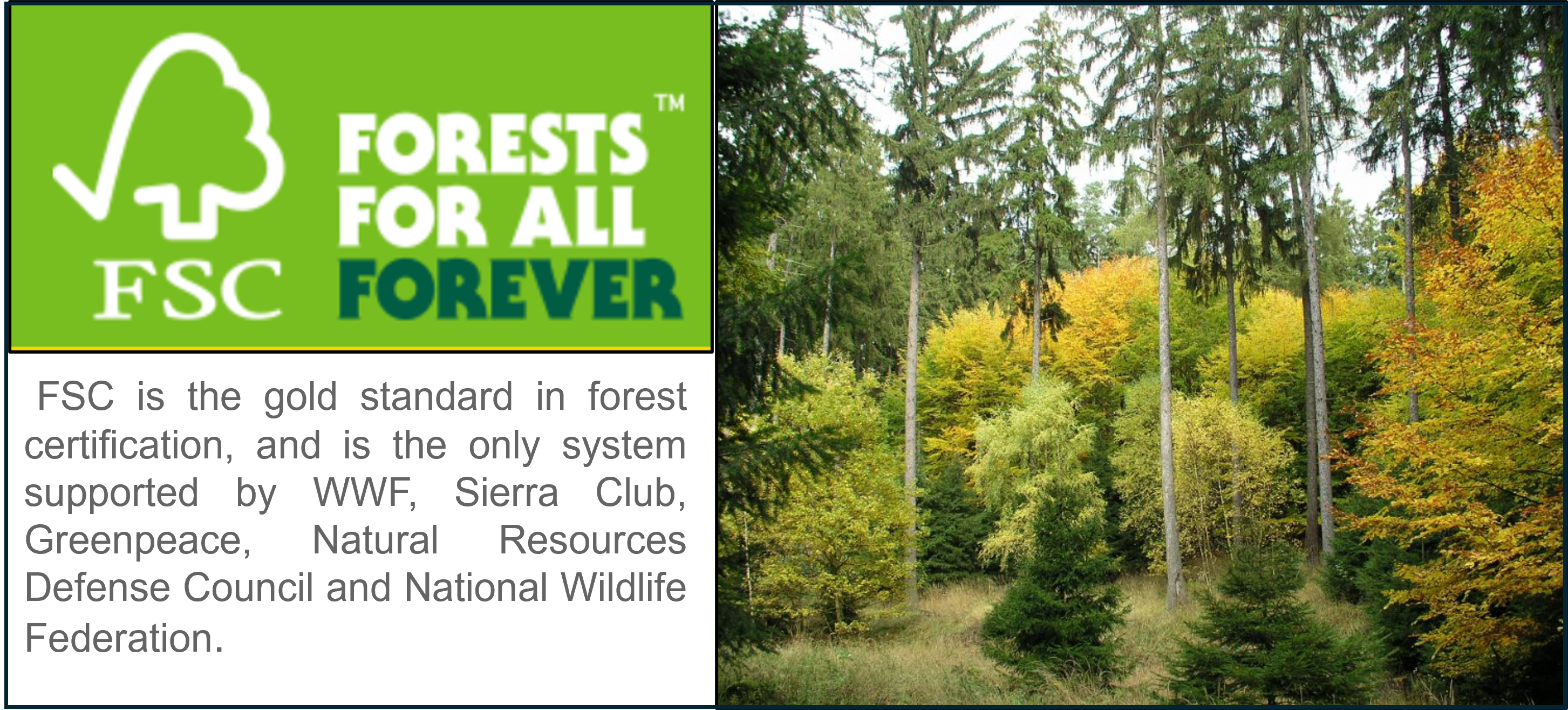

Our boards are packed in a 7-ply white cardboard box desigmed to keep the board intact and free from damage during the delivery process. Included in the box are the following:

Cutting board wrapped in honeycomb paper. We don’t use any plastic such as bubble wrap.

A set of 4 wooden feet made from the same material as your

board. The feet are complementary, to self-install if you prefer.A set of 4 felt pads to install with the feet

A set of 4 stainless steel screws to install the feet.